CH RG

CARACTERÍSTICAS

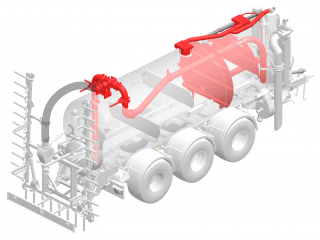

● Cisternas com eixos autodirecionais de série (2 e 3 eixos)

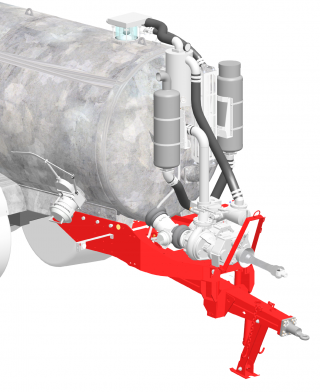

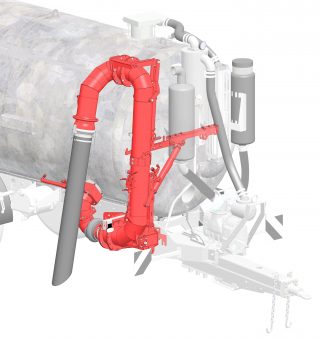

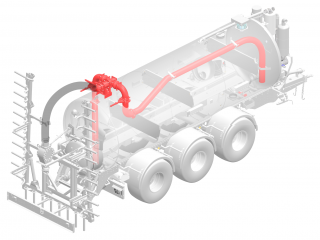

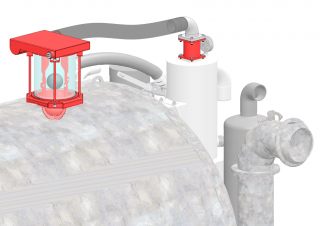

● Inversor hidráulico na bomba (de série para ≥ CH 18000 RG)

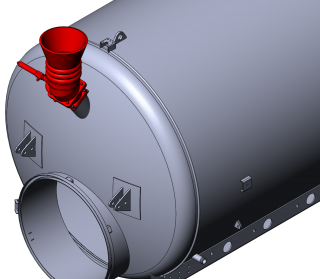

● Depósito galvanizado e indicador de nível tubular

● Iluminação LED

● Lança com mola, regulável em altura, com argolão flangeado giratório Scharmuller®

● Dois tubos flexíveis com engates rápidos

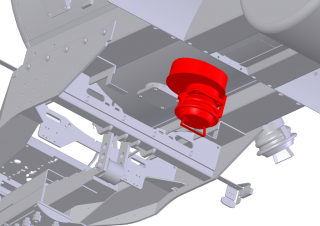

● Descanso hidráulico

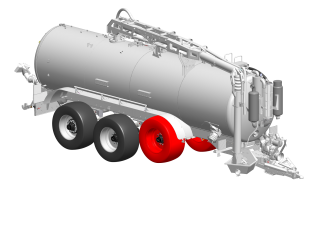

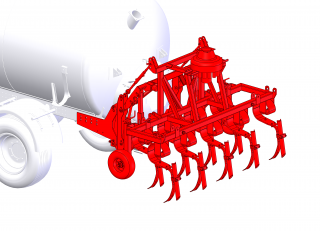

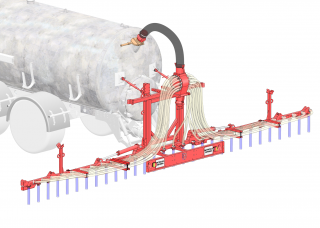

● Dispersor fixo de leque

● Eixos e rodas configuráveis

● Duas adufas: uma hidráulica de duplo efeito e outra mecânica

● Porta traseira autoclave para limpeza

● Pré-preparação para inserção de localizadores

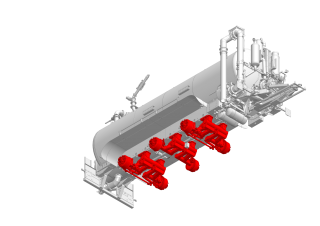

● Anteparas interiores anti balanço

● Dispositivos de segurança, iluminação e sinalização de acordo com a legislação em vigor

![]()

Versão com travagem pneumática disponível sob consulta.

Produto Standard

| Características | CH 10000 ES | CH 12000 ES | CH 12000 RG | CH 14000 RG | CH 16000 RG | CH 18000 RG | CH 22000 RG | CH 22000 RG | CH 24000 RG | |

| Peso total indicativo | t | 5 | 5,3 | 5,74 | 5,94 | 6,14 | 6,34 | 7,35 | 7,9 | 9 |

| Massa técnica total | t | 15,5 | 15,5 | 24 | 24 | 24 | 26 | 26 | 27 | 33 |

| M.M.T.A. no(s) eixo(s) (≤40 Km/h) | t | 12,5 | 12,5 | 21 | 21 | 21 | 23 | 23 | 24 | 30 |

| M.M.T.A. no ponto de engate | t | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Capacidade | l | 9700 | 11700 | 11750 | 13450 | 15800 | 17800 | 22000 | 22000 | 24100 |

| Tipo de chassi | – | Autoportante | Autoportante | Autoportante | Autoportante | Autoportante | Autoportante | Autoportante | Autoportante | Autoportante |

| Dimensões | ||||||||||

| Comprimento/Diâmetro do tanque | m | 4,56×1,75 | 5,32×1,75 | 5,19×1,75 | 5,10×1,90 | 5,94×1,90 | 6,00×2,00 | 7,51×2,00 | 7,52×2,00 | 8,46×2,00 |

| Diâmetro da porta de Homem (Autoclave) | mm | 950 | 950 | 950 | 950 | 950 | 950 | 950 | 950 | 950 |

| Diâmetro adufa, tubos e acessórios | mm/’’ | 200/8 | 200/8 | 200/8 | 200/8 | 200/8 | 200/8 | 200/8 | 200/8 | 200/8 |

| Comprimento total | m | 6,78 | 7,55 | 7,44 | 7,3 | 8,14 | 8,16 | 9,74 | 9,72 | 10,62 |

| Largura total | m | 2,5 | 2,5 | 2,5 | 2,55 | 2,55 | 2,55 | 2,55 | 2,55 | 2,55 |

| Altura total | m | 3,1 | 3,1 | 3,08 | 3,19 | 3,19 | 3,25 | 3,39 | 3,39 | 3,45 |

| Diâmetro do indicador de nível | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Suspensão, eixo(s) e rodas | ||||||||||

| Tipo de suspensão | – | – | – | Bogie | Bogie | Bogie | Bogie | Tandem | Tridem | Tridem |

| Tipo de eixo | – | 1 Eixo Fixo | 1 Eixo Fixo | Autodirecional (2º) | Autodirecional (2º) | Autodirecional (2º) | Autodirecional (2º) | Autodirecional (2º) | Autodirecional (1º e 3º) | Autodirecional (1º e 3º) |

| Quadrado – (N.º de pernos) | mm – (n.º) |

150 – (10) | 150 – (10) | 110 – (10) | 110 – (10) | 110 – (10) | 110 – (10) | 150 – (10) | 130 – (10) | 150 – (10) |

| Cubos | mm | 406 x 140 | 406 x 140 | 406 x 120 | 406 x 120 | 406 x 120 | 406 x 120 | 406 x 120 | 400×120 | 406×120 |

| Via | mm | 1700 | 1700 | 1850 | 1850 | 1850 | 1850 | 1950 | 1950 | 1900 |

| Rodas | – | 600/55 R26.5 | 600/55 R26.5 | 600/55 R26.5 | 600/55 R26.5 | 600/55 R26.5 | 600/55 R26.5 | 600/55 R26.5 | 560/60 R22.5 | 600/55 R26.5 |

| Equipamento Standard | ||||||||||

| Bomba compressora | – | STAR 60 | STAR 72 | STAR 72 | STAR 72 | STAR 72 | DL 180 | DL 180 | DL 180 | DL 180 |

| Comprimento tubos sucção | m | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 | 2 x 3,3 |

| Pré-instalação para braço de carga | – | Sim | Sim | Sim | Sim | Sim | Sim | Sim | Sim | Sim |

| Descanso | – | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível | Hidráulico rebatível |

| N.º anteparas interiores | – | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 |

| Cardan | – | Fusível | Fusível | Fusíve | Fusível | Fusível | Homocinético | Homocinético | Homocinético | Homocinético |

Quer configurar o seu modelo Standard?

Faça o seu pedido de manual de utilizador e lista de peças de reposição do seu equipamento

Consigo no terreno

___________________________________________________