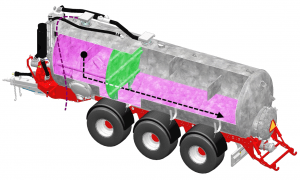

Sistema de Transferência de Carga

Quantas vezes sentiu falta de aderência e tração durante o espalhamento de chorume líquido em terrenos inclinados?

Este é um dos problemas mais recorrentes, especialmente em zonas de inclinação acentuada, devido ao excesso de peso na traseira causado pela concentração chorume líquido. A solução desenvolvida pela Herculano pretende promover a estabilidade da cisterna durante o espalhamento, beneficiando a tração em zonas inclinadas, até que a cuba fique completamente vazia.

Este sistema de transferência de carga tem como base uma divisória na zona frontal no interior da cuba, originando uma antecâmara com um volume aproximado de 1/3 do volume total da cisterna. Através deste sistema, consegue-se manter mais peso no argolão durante o espalhamento, melhorando assim a aderência e a capacidade de movimentação do trator.

Como funciona?

Durante o enchimento, ambas as câmaras da cuba enchem em simultâneo, no entanto, durante o espalhamento (por pressão), o líquido existente na antecâmara da frente irá permanecer até que o nível da câmara de trás atinja o bocal inferior de comunicação da divisória. Só depois do nível de líquido atingir esse bocal, é que se inicia automaticamente a descarga da divisória frontal mantendo, desta forma o equilíbrio da cisterna até ao final do processo.

Este é um opcional na gama de cisternas, especialmente desenvolvido e adequado para cisternas com dispositivos de espalhamento e localização de chorume líquido, disponível para os modelos de maior capacidade, a partir da CH12000.