H2RS – produto no terreno, espalhamento uniforme

Na gama H2RS não há uma solução vencedora, por isso optámos por criar vários tamanhos à medida do cliente surgindo desta forma os modelos: H2RS9, H2RS11, H2RS12, H2RS14, H2RS18 e H2RS18RG, é por isso que cada espalhador é fabricado individualmente com componentes padronizados. Durante o fabrico, damos especial atenção à sua futura máquina.

Uma vez que este produto sofre muito com o trabalho a que se destina, o conhecimento de processamento de aço e a escolha do material são essenciais. As matérias primas escolhidas tem alta resistência ao desgaste começando pelas chapas do fundo e as laterais, a corrente marítima de grau 80 e também os tubos FERPINTA® que arrastam o material.

Esta gama de espalhadores HERCULANO têm um grande equipamento standard:

• grupos de rolos com espirais para uma divisão intensa e uma grande projeção;

• eixo de transmissão e eixo T.D.F. reforçado;

• controlo da unidade da esteira em movimento por regulador com pressão constante;

• correntes da esteira de transporte de material com grau 80;

• tensão da esteira fácil de alcançar, localizada fora da caixa monocoque e com mola de compensação para o ajuste;

• lubrificação central de massa para componentes que tem difícil acesso.

PONTOS GERAIS

Qualquer modelo é muito multifuncional na disseminação e transporte de vários materiais. O grupo de rolos pode ser facilmente removido, pois é aparafusado à caixa monocoque, convertendo-o num reboque de silagem ou outro.

O fundo soldado tem uma esteira reforçada com várias vantagens: a esteira tem elo de emenda que facilita as operações de manutenção, o veio principal da esteira pode ser removido pela traseira em conjunto com as estrelas de tração. Além disso, as roldanas são feitas de aço de construção ao carbono de Ø 120 e as duas esteiras estão equipadas com um separador central, que impedem a acumulação de produto no centro da caixa deixando-a completamente limpa (modelos H2RS12 a H2RS18RG)

ALGUMAS OPÇÕES:

-GRUPO DE ROLOS

O grupo de rolos é aparafusado à caixa, de fácil remoção e pode de ser substituído por outro mais alto 250mm ou até reforçado para produtos mais densos. Com isso são instalados extras na porta para que esta fique no nível do novo grupo, evitando assim perdas de carga durante o transporte e permitindo regular o fluxo de material durante o espalhamento mesmo com este extra.

-MOVIMENTO DA ESTEIRA

É disponibilizada uma regulação manual da esteira para o movimento da mesma, mas como opção também existe a possibilidade de instalação, para comodidade do utilizador, uma regulação elétrica e essa poder ficar dentro da cabine do trator.

-REDUTOR EXTRA

O redutor extra é adicionado na ponta oposta do veio onde está instalado o redutor já existente e é normalmente utilizado para produto mais pesado em que seja solicitado mais esforço à unidade transmissora da esteira. Existe também a possibilidade de trabalho com um redutor apenas ou com os dois redutores em simultâneo.

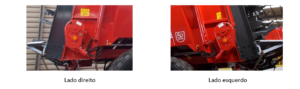

-INDICADOR NIVEL PORTA

Serve para indicar ao condutor, estando este dentro da cabine, através de um nível à frente do reboque, qual a posição da abertura da porta traseira.

-PORTAS LIMITADORAS

Aplicação de portas no grupo de rolos que podem limitar lateralmente o espalhamento do produto.