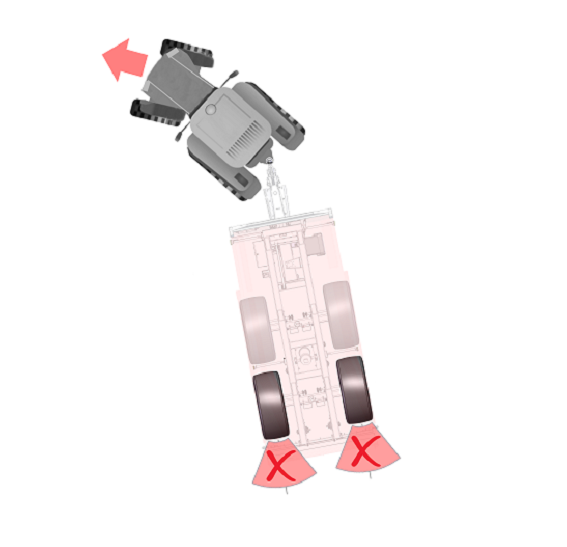

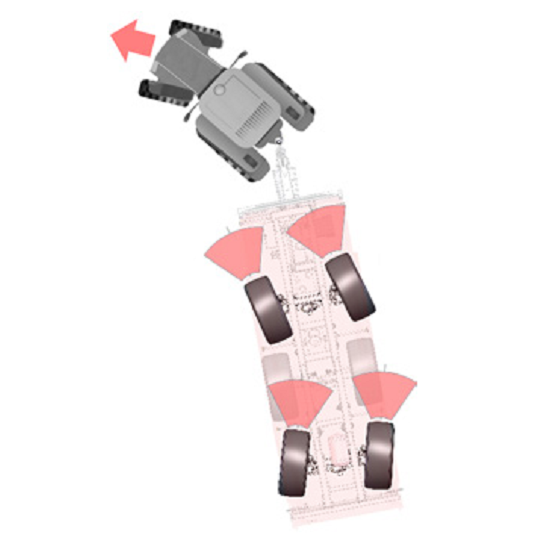

Os incêndios florestais representam uma ameaça constante às áreas rurais, exigindo uma resposta rápida e eficaz. O Kit de Incêndios, composto por um grupo motobomba, mangueiras e uma pistola comumente usadas nas corporações de bombeiros, é uma solução robusta e versátil que pode ser montada em reboques-cisterna e reboques-tanque. Rebocados por tratores agrícolas, estes equipamentos permitem uma intervenção imediata, servindo como o primeiro recurso disponível em caso de emergência.

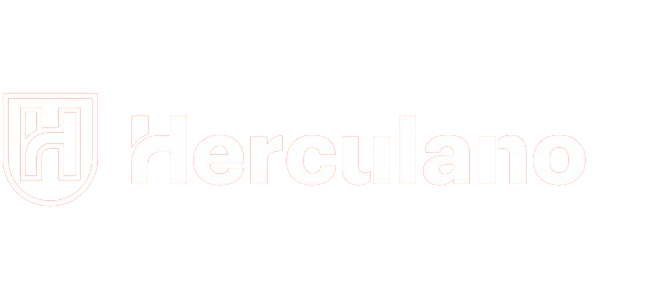

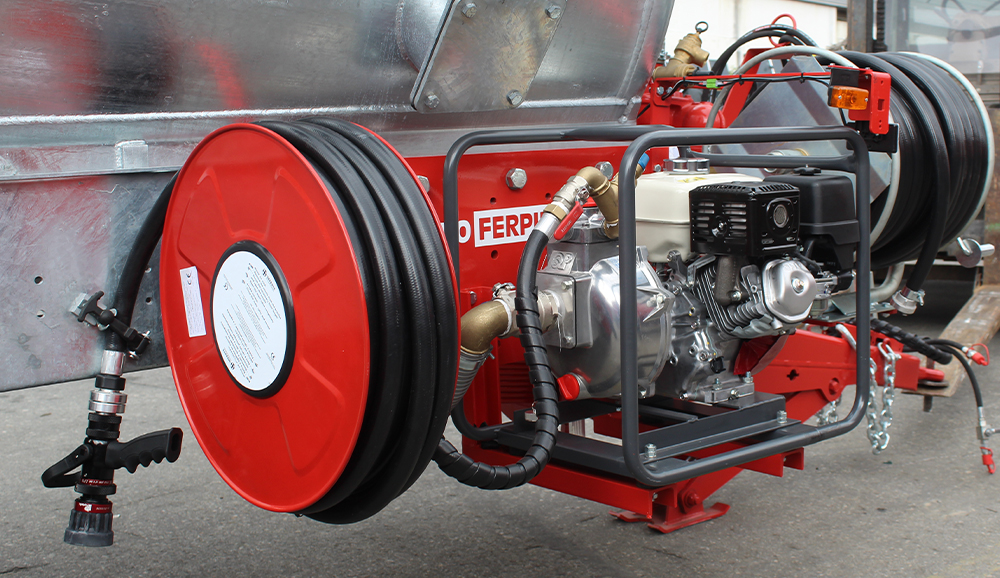

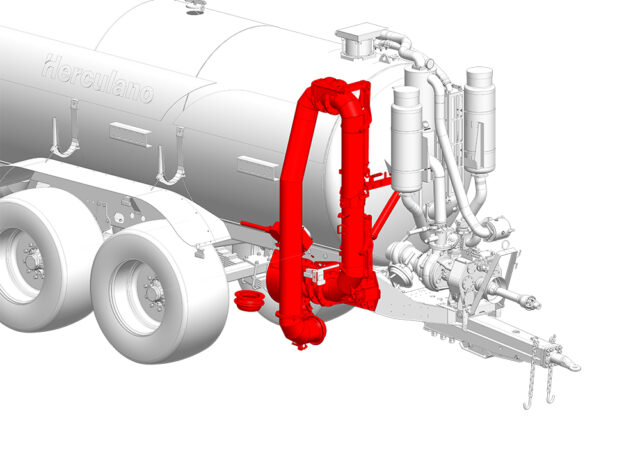

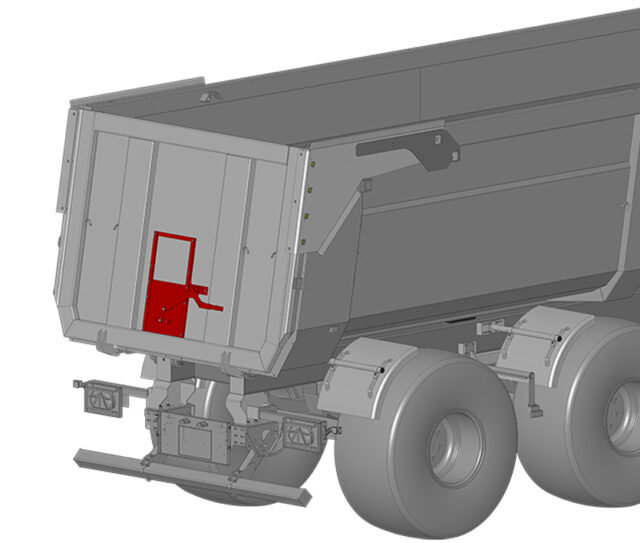

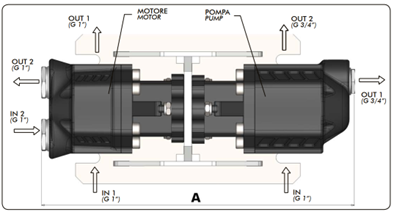

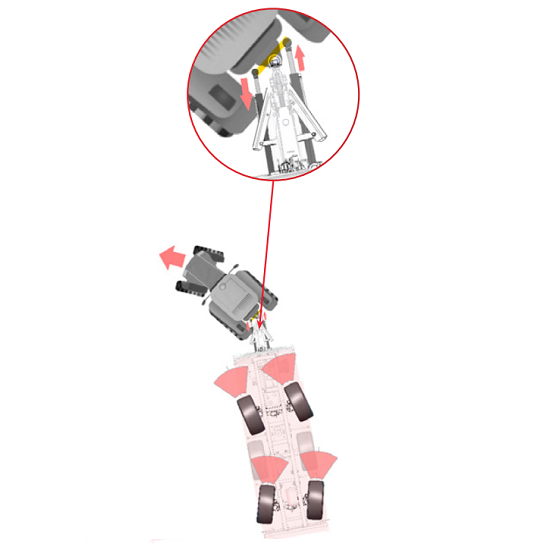

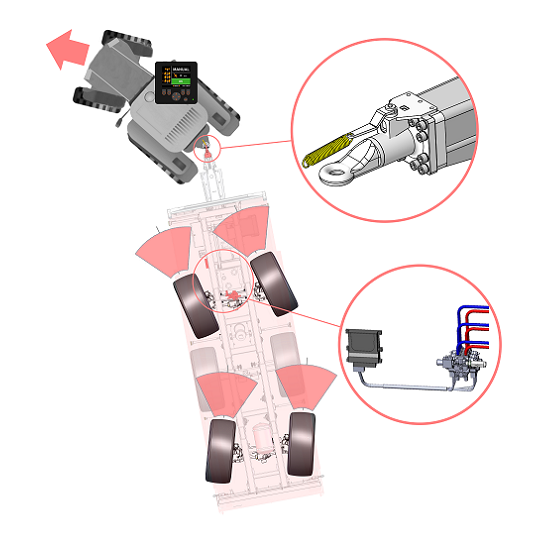

Esta solução é constituída por motor a gasolina e uma bomba com capacidade de 480 litros por minuto (l/min), com uma pressão de trabalho de 10 bar, garantindo um fluxo de água consistente e potente durante o combate ao incêndio. O sistema inclui ainda dois enroladores com 3 x 25 metros de mangueira semi-rígida, com diâmetro de 25 mm, permitindo uma boa flexibilidade e alcance na distribuição da água. Para facilitar o manuseio e aumentar a eficiência da operação, o sistema é equipado com engates Storz e uma agulheta Protek, proporcionando maior segurança e rapidez no estabelecimento da linha de combate.

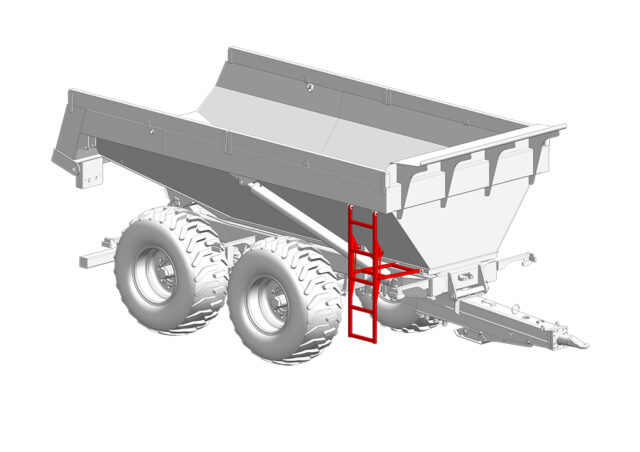

Este equipamento é especialmente valorizado por empresas de exploração florestal e juntas de freguesia, que o utilizam como recurso primordial para o ataque a incêndios antes da chegada de meios de combate profissional. A sua mobilidade e autonomia proporcionada pelo sistema de bombagem tornam-no ideal para operar em terrenos difíceis e de difícil acesso, onde a presença de fontes de água é limitada.

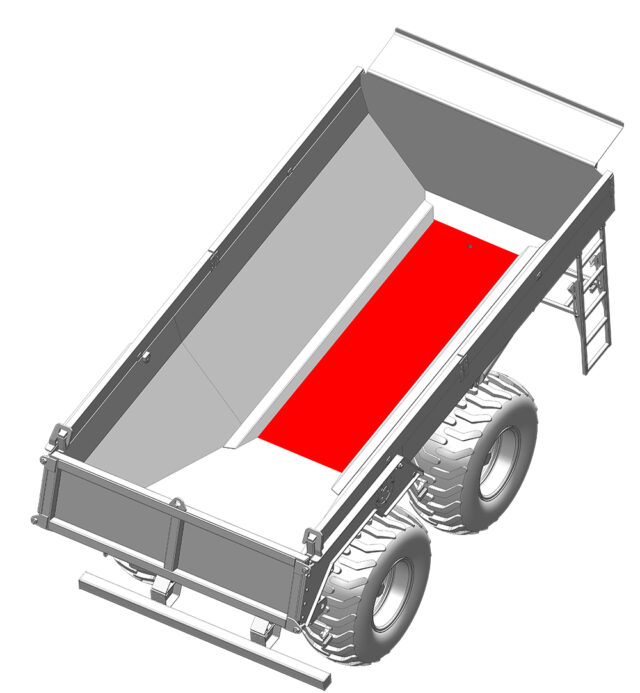

Além do combate direto a incêndios, o Kit de Incêndios pode ser utilizado em várias outras aplicações, como a lavagem de estradas, rega de jardins municipais e manutenção de árvores ornamentais. A versatilidade do reboque-tanque permite a adaptação a diferentes necessidades, oferecendo uma solução eficiente e prática para a gestão de recursos hídricos em ambientes urbanos e rurais.

Além disso, pode ser utilizado em ações preventivas, como o humedecimento de áreas sensíveis e a criação de faixas de contenção. A sua presença nos reboques agrícolas amplia significativamente a capacidade de atuação das comunidades locais, garantindo maior proteção ao património florestal, agrícola e urbano.

Com um design pensado para máxima eficiência e facilidade de utilização, este sistema representa um investimento estratégico na segurança e gestão de recursos hídricos, reforçando a capacidade de resposta em momentos críticos.